Winding Resistance Testing / Measurement

saurabh engineering services

Winding Resistance Testing / Measurement

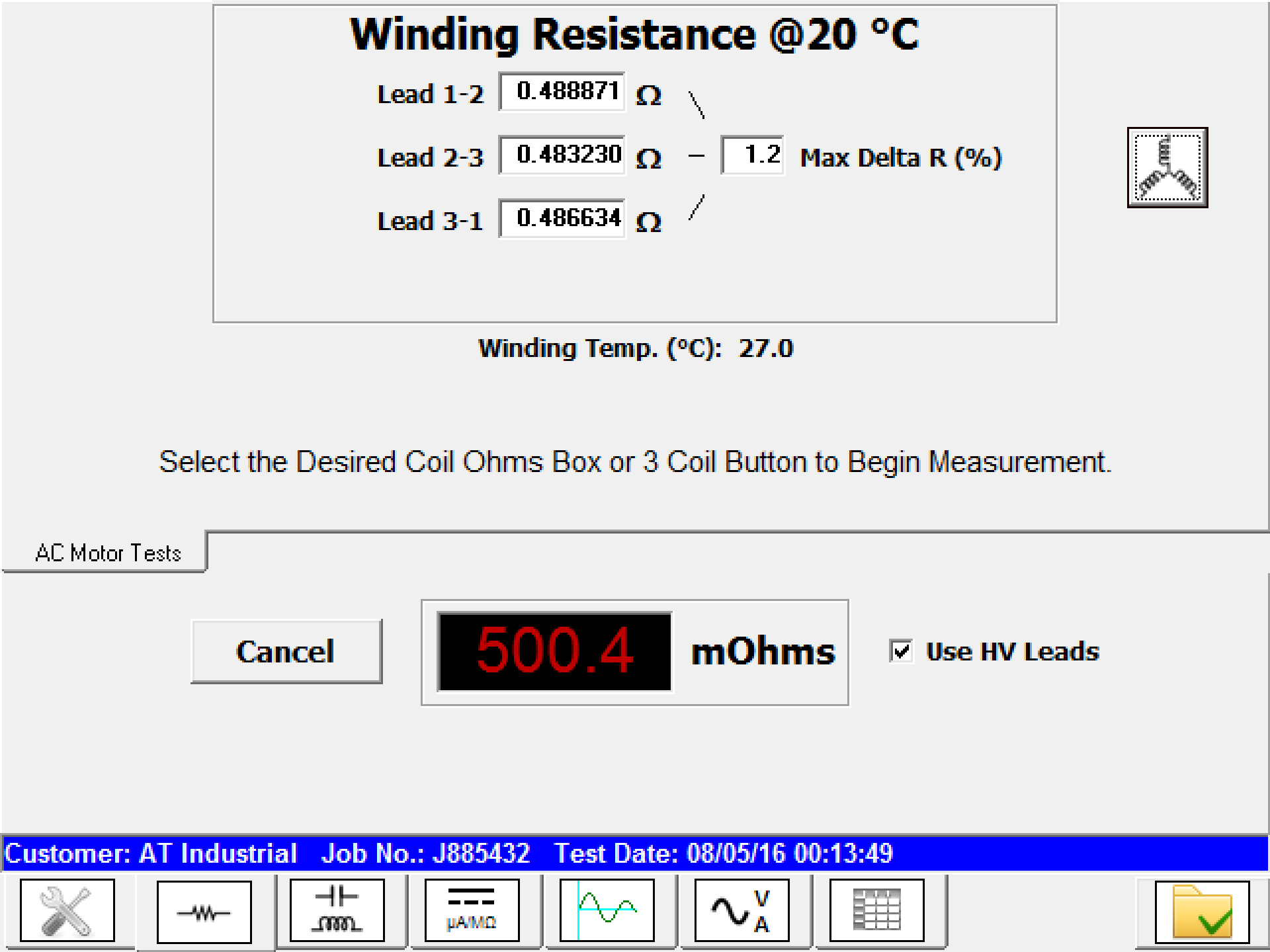

Winding resistance testing of motors is important because it helps to assess the condition of the windings, detect potential issues, and ensure the efficient and reliable operation of the motor. Here are some reasons why winding resistance testing is essential:

- Identify manufacturing defects: Winding resistance testing can help identify issues that may have occurred during the motor’s manufacturing process, such as improper winding connections, incorrect wire size, or poor insulation quality. Identifying and correcting these defects early can prevent premature motor failure and save on costly repairs or replacements.

- Detect winding damage: Over time, factors like excessive heat, overloading, vibration, and moisture can cause damage to the motor windings. Winding resistance testing can reveal changes in the resistance values, indicating potential winding damage or insulation breakdown that could lead to motor failure if left unaddressed.

- Identify connection issues: Winding resistance testing can help identify loose or poor connections within the motor windings. These connection issues can result in increased resistance, reduced motor efficiency, and potential motor failure. Identifying and correcting these issues can improve motor performance and extend its service life.

- Monitor insulation aging: Insulation around the windings can degrade over time due to thermal stress, mechanical stress, and environmental factors. Winding resistance testing can help detect changes in resistance values that may indicate insulation degradation, which can lead to short circuits, reduced motor efficiency, or even catastrophic motor failure.

In India, as per CEA Regulation 2010, Rule No.42, ELCB Installation is mandatory for all 3 Phase Loads and Load above 5KW for Single Phase.

- Evaluate repairs and maintenance: After motor repairs or maintenance, winding resistance testing can confirm that the work was performed correctly and that the motor is safe to operate. It can also help detect any new issues that may have been introduced during the repair process.

- Quality control and acceptance testing: For new motors or motors that have been refurbished, winding resistance testing can serve as a quality control measure and acceptance test, ensuring that the motor meets specifications and is in good working condition before it is put into service.

- Establish a baseline for future comparison: Performing winding resistance testing on a regular basis helps establish a baseline for the motor’s winding resistance values. This baseline can then be used to track changes over time and provide an early warning of potential issues before they become critical.

In summary, winding resistance testing of motors is a crucial aspect of motor maintenance, diagnostics, and quality control. It helps to ensure the efficient and reliable operation of the motor, prevent unexpected failures, and extend the motor’s service life.

To ensure proper working of ELCB/RCCB, they should be tested periodically, at least once in year.

SES

Need Help?

Don’t hesitate to contact us for more information about company or service.